THE IRZ-400 SERIES VFDs control, protect, verify parameters, and regulate rotation frequency of SRP or PCP systems arranged with surface three-phase induction or permanent magnet motors.

Main feature of the smart VFD is that user can build up calculated dynamometer chart without dynamograph or other sensor mounted on moving parts of the pump system.

Using VFD, customer is able to CONSTANTLY MONITORING operation of the pumping equipment, as well as pump fill factor and well production rate.

Adjustable graphic presentation of any parameter on the drive’s display or a PC

Load curve drawing without a dynamograph

| Parameter | Value |

|---|---|

| Supply voltage | 275…475 V (380 +25%-25%V), 340…550 V (480 +15%-30%) |

| Power range of electric motor to be connected | 5—75 kW |

| Range of regulated rotation frequencies | 0.5—100 Hz (resolution 0.1) |

| Relative error of current, voltage and rotation frequency measurement and time setting | 2% |

| Enclosure protection class | IP54/IP66 |

| Operating temperatures | -60…+50 °С (-76…122 °F) |

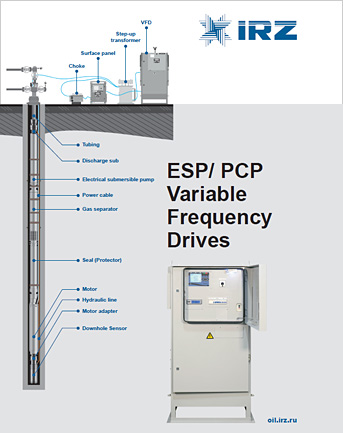

Operation, control and protection of submersible electric motors with power ranging from 3 to 250 kW.

The family of IRZ variable frequency drives ensures control, parameters monitoring and protection of induction and permanent magnet motors of electric submersible pumps and progressive cavity pumps enabling soft start, soft stop, and…

Parameters monitoring, control and protection of motors with power ranging from 14 to 320 kW and possibility of soft start and stop.

The IRZ-400 Series VFDs control, protect, verify parameters, and regulate rotation frequency of SRP or PCP systems arranged with surface three-phase induction or permanent magnet motors.