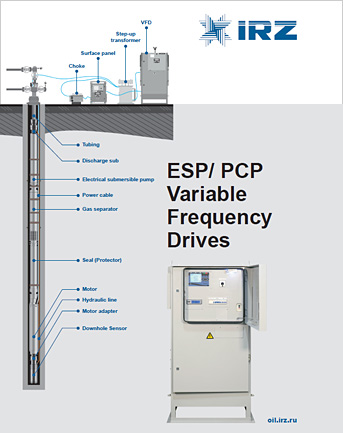

THE FAMILY OF IRZ VARIABLE FREQUENCY DRIVES ensures control, parameters monitoring and protection of induction and permanent magnet motors of electric submersible pumps and progressive cavity pumps enabling soft start, soft stop, and rotation frequency regulation.

The IRZ drives are used by oil companies to protect downhole equipment and increase run life of pump systems.

| Parameter | Value |

|---|---|

| Supply voltage, V | 275…475 V (380 V +25%-25%), 340…550 V (480 V +15%-30%) |

| Supply frequency | 49…51 Hz (with input harmonics filter) 45…55 Hz (without input harmonics filter) |

| Ambient temperature | -60…+50 °С |

| Type of motor | Induction & PMM — the mode is selectable in the drive menu |

| Max motor power | |

| — 6-, 12-, 18-pulse | 40 / 60 / 100 / 140 / 230 / 380 / 410 / 480 h.p. |

| — AFE | 410 h.p. |

| Efficiency | ≥ 95 % |

| Monitoring of motor operating current | |

| — Range | 0…1.25 x Inom |

| — Relative error | 2 % |

| Monitoring of insulation resistance of the “Transformer-Cable-Motor” line | |

| — Range | 0…1 MOhm, 1…10 MOhm |

| — Relative error | 2.5 %, 10% |

| Monitoring of backspin rotation frequency | |

| — Range | 1…50 Hz |

| — Relative error | 2 % |

| Monitoring of effective linear voltage | |

| — Range | 0…600 V |

| — Relative error | 2 % |

| Enclosure standard | IP43, IP54 or higher at request |

| Interfaces | — USB — RS232/RS485 — Ethernet — Optional GPRS/Wi-Fi modem — NC/NO dry contacts — Two 0—10V / 4—20 mA DC analog inputs — Five discrete inputs |

Operation, control and protection of submersible electric motors with power ranging from 3 to 250 kW.

The family of IRZ variable frequency drives ensures control, parameters monitoring and protection of induction and permanent magnet motors of electric submersible pumps and progressive cavity pumps enabling soft start, soft stop, and…

Parameters monitoring, control and protection of motors with power ranging from 14 to 320 kW and possibility of soft start and stop.

The IRZ-400 Series VFDs control, protect, verify parameters, and regulate rotation frequency of SRP or PCP systems arranged with surface three-phase induction or permanent magnet motors.