THE IRZ TMS DOWNHOLE MONITORING SYSTEMS ensure sustained real-time monitoring of all practically required downhole parameters of electrical submersible pump (ESP) system, such as pump intake pressure and temperature, motor oil/winding temperature, motor vibrations, current leakage, and pump discharge pressure, as well as up to 24 optional parameters depending on additional equipment in use with the sensor (i.e. anti-scaling electromagnetic unit, motor RPM measuring unit, etc.)

Data provided by IRZ TMS helps preserve ESP, increase pump run life, and optimize oil production. High reliability of new downhole monitoring system is ensured by two standalone electronic modules set in the sensor: active one in operation, and the second on standby mode. Should the main module fails, the system will switch over to the standby module, either by operator’s command or automatically, assuring trouble-free operation of the entire system.

| Monitored parameters | IRZ TMS |

|---|---|

| Intake pressure | |

| — Range** | 0—5700 psi |

| — Resolution | 0.1 psi |

| — Accuracy* | ±0.5 % FS |

| — Update time | ≤ 5 s |

| Intake temperature | |

| — Range*** | 0—150 °С / 0—175 °С |

| — Resolution | 0.01 °С |

| — Accuracy* | ±1 % FS |

| — Update time | ≤ 30 s |

| Motor oil or winding temperature | |

| — Range | 0—250 °С |

| — Resolution | 0.01 °С |

| — Accuracy* | ±1 % FS |

| — Update time | ≤ 30 s |

| Motor vibrations (X, Y, Z) | |

| — Range | 0—5 g |

| — Resolution | 0.01 g |

| — Accuracy* | ±5 % FS |

| — Update time | ≤ 30 s |

| Insulation resistance (current leakage) | |

| — Range | 0—10 MОhm (0—20 mA) |

| — Resolution | 1 kOhm (0.001 mA) |

| — Accuracy | ±2—5 % FS (+/- 0.05 % FS) |

| — Update time | ≤ 30 s |

| Discharge pressure | |

| — Range** | 0—5700 psi |

| — Resolution | 0.1 psi |

| — Accuracy* | ±0.5 % FS |

| — Update time | ≤ 30 s |

* Higher accuracy is available upon request

** Optionally 0-60 MPa (8700 psi)

*** Hi-temp version 175 °С available in Q3 2019

| Parameter | Value | |

|---|---|---|

| Connection and data communication | The DH sensor is connected to motor Y-point. Power supply and data communication are provided via ESP cable, hydraulic control line to gauge discharge pressure | |

| Motor adapter | Designed based on motor drawing | |

| Operating temperature range for Surface Readout Unit, °С | Downhole sensor & motor adapter D-sub | Carbon steel with anticorrosion coating or stainless steel |

| Hydraulic tube | Stainless steel | |

| Downhole sensor | OD ≤ 95 mm (3.74’’), 2—3/8’’ EU 8RD box thread at the bottom (or other upon request) | |

| D-sub | OD ≤ 92 mm (3.62’’) 3—1/2’’ EUE box & pin threads (or other upon request) |

|

| D-sub inside hole diameter | ≥ 62 mm (2.44’’) | |

| Motor temperature measuring options | Thermal pin for motor oil temperature & thermocouple connector for motor winding temperature measurement | |

| Parameter | Value |

|---|---|

| Supply voltage | 85—400 V, 50 Hz / 60 Hz |

| Interfaces | — 1 RS485 port and 1 universal RS232/RS485 port — 1 USB-host port — 8 analog outputs 4—20 mA and/or 0—10 V — 8 analog inputs 4—20 mA and/or 0—10 V — Ethernet and wireless (GPRS) channel for SCADA network |

| Enclosure | IP65 or higher (upon request) |

| Temperatures range | -40…+70 °С |

| Graphic display | 6'' |

| Data on display | Represented in digits |

| Logging | 10 MB |

| Data after saving to USB-drive | Can be represented on PC in the form of digits or charts using special software |

| Pump protection | 1 tripping relay for ESP shutdown by high Tmot, low Pi, high vibrations and ground fault |

| Protocols of data exchange with VFD | UNICONN, INSTRUCT, IRZ-TMS1, IRZ-TMS2, ELEKTON-TMSN1, ELEKTON-TMSN2, BORETS, and other MODBUS-based communication protocols |

| PC direct connection | Allows real-time data monitoring on PC |

| Menu language | English (other upon request) |

| Parameter | Value |

|---|---|

| Supply voltage | 170…285 V, 50 Hz |

| Interfaces | RS232 & RS485 ports |

| Enclosure | P23 |

| Temperatures range | -60…+70 °С |

| Protocols of data exchange with VFD | UNICONN, INSTRUCT, IRZ-TMS1, IRZ-TMS2, ELEKTON-TMSN1, ELEKTON-TMSN2, BORETS, and other MODBUS-based communication protocols |

| Parameter | Value |

|---|---|

| Motor operating linear supply voltage | 5 kV |

| Enclosure | IP54 or higher (upon request) |

| Temperatures range | -55…+85 °С |

IRZ TMS downhole sensor system is used as a part of electric submersible pumps (ESP).

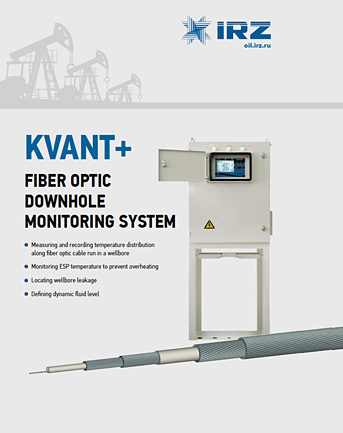

The permanent downhole gauges of IRZ are designed to monitor realtime parameters of a rod-pump/ PCP system or a gas lift/ flowing well: tubing & annulus pressure, annulus temperature, and tubing X, Y, Z-axis vibrations.

IRZ TMS system with thru shaft is designed for dual completion wells with one motor and two pumps.

IRZ TMS-ORD2 integrated system with thru shaft is designed for dual completion wells with one motor and two pumps.

IRZ TMS-ORD4 integrated system has been designed together with OOO “NPF Paker” and is intended for dual completion wells equipped with one ESP.