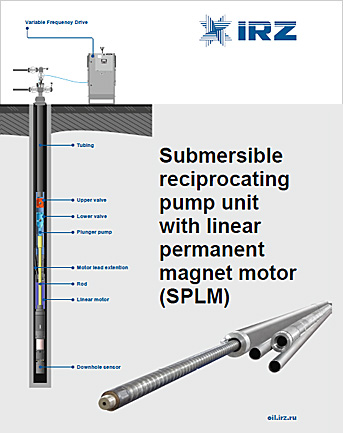

Oil production, monitoring of equipment and well parameters in horizontal, vertical, and inclined wells with 0.5—30 m3/day production rate and up to 3 000 m depth.

The reciprocating rotor (hereinafter “slider”) of the submersible pump is driven by a linear permanent magnet motor installed below the pump.

The linear motor comprises a fixed round stator and rod with permanent magnets. The stator consists of three-phase winding cylindrical coils that are connected in series and powered by a variable frequency drive. The stator coils generate a travelling magnetic field that induces an electromotive force to move the magnetic slider which pushes the plunger pump rod.

Universal digital downhole sensor installed below the motor allows for real-time reading such oil production parameters as follows:

The system is equipped with a variable frequency drive which along with the digital downhole sensor helps to increase oil production and protects the motor due to:

The variable frequency drive ensures easy and convenient change and adjustment of well operating parameters, as well as remote monitoring and control of oil production process.

The combination of a motor, pump and VFD is selected according to the installation depth, production rate, viscosity, and other parameters of the well.

| Parameter | Value |

|---|---|

| Overall dimensions (system) | Ø 117 * 9 600 mm |

| Overall dimensions (stator) | Ø 117 * 6 240 mm |

| Slider stroke | 1 260 mm |

| Power | 35 kW |

| Voltage | 900 V |

| Maximum output current | 30—80 A |

| Traction force | 2.4 ton |

| Pump flowrate range | 0.5—30 |

| Operating temperature | 0…+150 °С |

| Well static pressure | 0—30 m3/day |

SPLM system is cost effective, power efficient, and environmental friendly version of sucker-rod pump system. Moreover, SPLM is able to effectively replace ESP systems at marginal wells without infrastructure conversion.

| Parameter | SRP | ESP | SPLM |

|---|---|---|---|

| Production, m3/day | <30 | >15 | <30 |

| Running depth, m | <2 000 | <3 000 | <3 000 |

| Operating mode | constant | periodic | constant |

| Unit power consumption, kW/t | 20 | 10 | 8 |

| Wellhead setup | required | no | no |

Oil production, monitoring of equipment and well parameters in horizontal, vertical, and inclined wells with 0.5—30 m3/day production rate and up to 3 000 m depth.